Evaporation, condensation and recuperation

Efficient heat transfer systems are essential in generating electricity from geothermal energy and waste heat. Getting the most from these systems requires careful planning and proper system design. Whether boiling, condensing organic fluids and/or recuperating waste heat for reuse, Alfa Laval has Organic Rankine Cycle expertise, equipment and services to support your renewable power plant.

Optimizing Organic Rankine Cycle heat recovery

Organic Rankine Cycle projects are most commonly built as modular systems using compact heat exchangers. Alfa Laval offers a wide array of plate-based solutions that are well suited for the evaporation, condensation and recuperation duties. We can help you optimize your heat and mass balance as well as select the right heat transfer equipment to deliver the optimal performance for your renewable power plant. We evaluate your requirements and recommend the use of fully welded, semi-welded and/or gasketed heat exchangers based on numerous factors such as operating pressure, fouling issues, and requirements for safety, cleanability and reduced environmental impact.

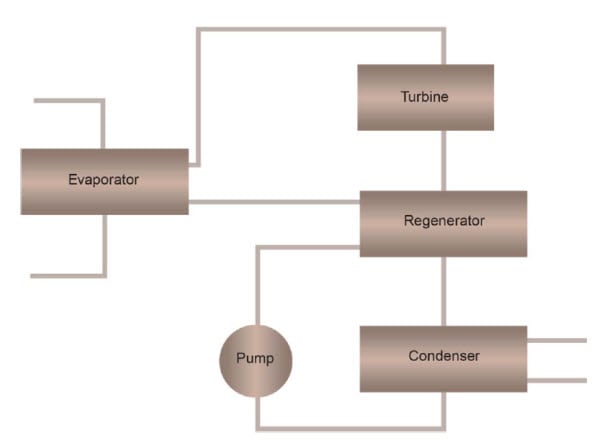

The Organic Rankine Cycle (ORC) system uses a process fluid such as a refrigerant or an ammonia-water mixture with a low boiling point to generate vapor from a low-grade heat source. The vapor drives the turbine and generator, then passes through a recuperator and condensor. A pump then transfers the process fluid through the recuperator back to the evaporator.

ORC process overview