Condition monitoring

Intelligent predictive maintenance systems that monitor the health of critical rotating equipment, such as pumps, reduce the risk of sudden failure and boost uptime and productivity. Alfa Laval condition monitoring systems leverage the internet of things (IoT), connected devices and analytics to maximize process throughput, reduce the total cost of ownership, and increase plant productivity.

Condition monitoring for complete 24/7 real-time visibility of pump health

- Focus attention and prioritize service for pumps using condition monitoring data and an intuitive user interface

- Cut maintenance costs by eliminating unplanned downtime, staff overtime and spare parts rush orders

- Extend pump lifetime and lower total cost of ownership

- Save valuable maintenance staff time and resources by focusing attention where it is needed most

- Service critical pumps only when maintenance is required using intelligent diagnostics

Industries that rely on rotating equipment spend billions on unplanned maintenance. Alfa Laval condition monitoring solutions are intelligent IoT systems that use advanced sensors to measure and collect critical data on machine vibration.

With Alfa Laval condition monitoring systems, plant operators have complete 24/7 visibility of machine health in real time from a remote location. They can predict, prioritize and plan condition-based maintenance activities using actionable machine health data and insights. This prevents equipment failure, optimizes asset performance and ensures production continuity.

Alfa Laval Analytics

Alfa Laval Analytics is a leading, AI-based solution for online condition monitoring. Analytics helps you detect potential machine failure before it occurs and diagnose the root cause. The user-friendly and affordable solution brings peace of mind and helps keep your pumps at peak performance at all times.

How do Alfa Laval condition monitoring systems work?

The Alfa Laval condition monitoring portfolio consists of:

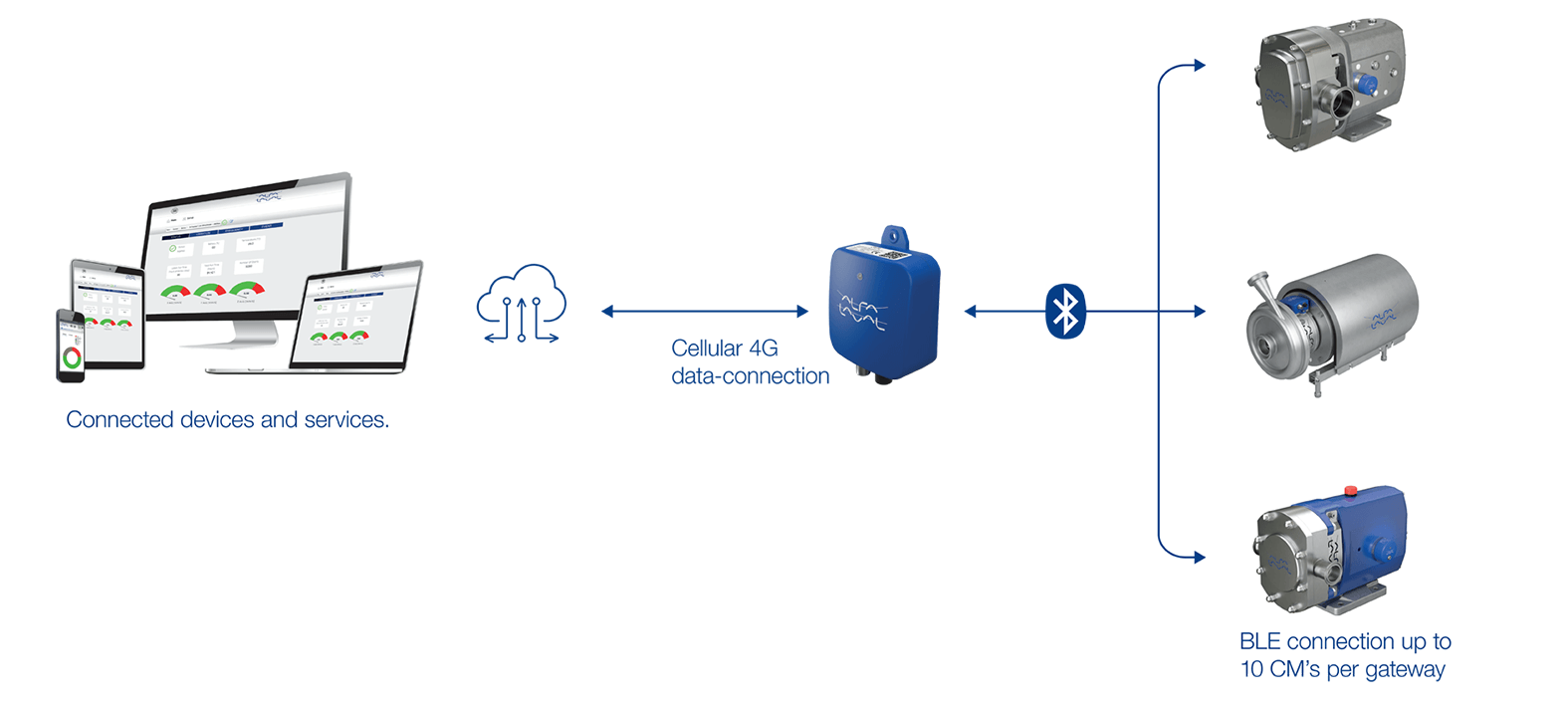

- Alfa Laval CM, a wireless monitoring unit that collects triaxial vibration data, surface temperature and run time of the pumps and transmits via Bluetooth to the CM Connect gateway.

- Alfa Laval CM Connect that transmits data to the cloud via 4G.

For complete visibility of pumps in a specific location, users access data and trend analyses using an intuitive web-based dashboard on PCs and mobile devices – anytime, anywhere. The dashboard displays pump health, battery status of the units, historical vibration data for FFT frequency analysis, current and total running hours, and pump information, such as serial number, model and type.

Using Alfa Laval service partners ensures easy access to service centres that use genuine Alfa Laval spare parts, maintain equipment reliability, and conduct maintenance under warranty.

Alfa Laval Connected Services subscription

The purchase of the Alfa Laval CM Connect includes a 12-month Connected Services subscription. Connected Services includes cellular connectivity, remote support during setup, access to data on current asset condition, and assistance in establishing a performance measurement baseline.

From any remote location, an unlimited number of users can monitor pump condition on PCs and mobile devices. An intuitive user interface and the CM Connect App presents data on an easy-to-understand dashboard and highlights assets in need of attention.

Get the full overview

Close at hand catalogue about pumps

At your fingertips: Alfa Laval hygienic pumps transfer products – safely, gently and efficiently. Our ‘Close at hand’ catalogue details everything you need to select reliable high-efficiency, energy-saving pumps while reducing emissions and water and energy use. What you get is increased safety, more uptime, and greater productivity.

Grow your business. Optimize your fluid handling systems – sustainably

Make your processes more efficient and more sustainable while achieving regulatory compliance and ensuring your business thrives. With Sustainable Optimization from Alfa Laval, you can save up to 80% in energy savings as well as 90% in water savings and cleaning media, while minimizing waste. Good for people. Good for planet. Good for profitability.

Bring your sustainability strategy to life

Get more energy and water savings and reduce emissions from your hygienic processing lines. Our monthly newsletter, near, brings you stories about how Alfa Laval can support you in improving environmental performance across the dairy, food, beverage, home-personal care and pharmaceutical industries. What’s good for people and planet is good for your business too.